A Comprehensive Guide to Bitumen 80/100: Properties, Applications, and Best Practices

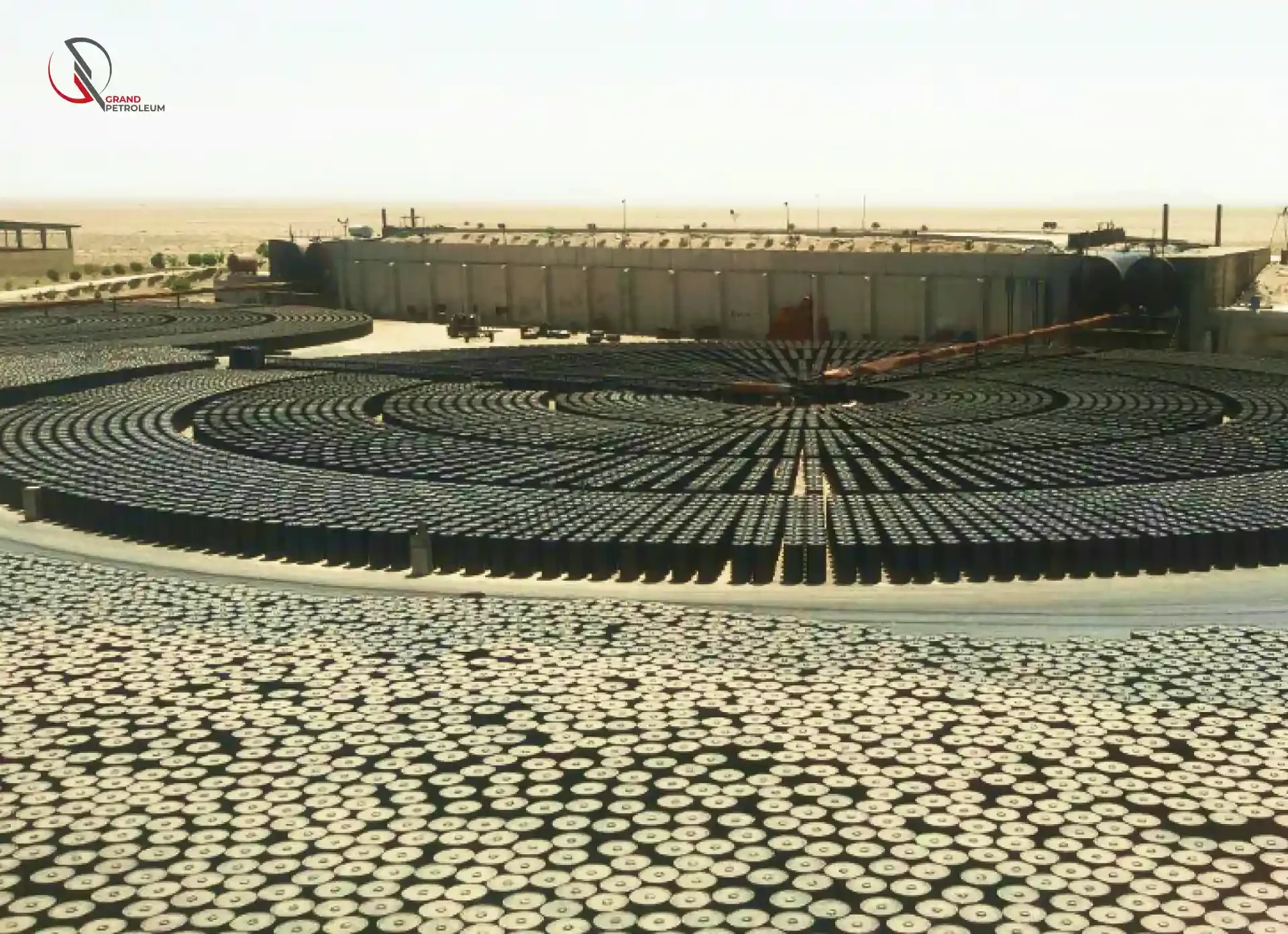

Bitumen is an essential material used widely in the construction industry and is available in the categories of Cutback bitumen, Pen grade bitumen, oxidation hardening bitumen, and polymer-modified bitumen, depending on the specific demand of various constructions. Bitumen 80/100 is one of the more popular grades due to its flexibility and suitability for its many uses in construction, such as in road building, roofing, and waterproofing. In this piece, we will strive to give a detailed insight into Bitumen 80/100, starting with the composition and ending with the proper usage of the product.

What is Bitumen 80/100?

80/100 bitumen is also referred to as Pen 80/100 bitumen. It is identified by its penetration value, which determines the firmness of the particular grade of bitumen. The penetration value is obtained from the penetration test, which is an empirical test, giving the depth (in hundredths of mm) to which a weighted needle is capable of penetrating a sample of bitumen under a given load within a specified time and at a defined temperature.

The numbers 80/100 in the designation bitumen 80/100 relate to penetration values likely to be obtained when testing this particular grade of bitumen. In more detail, Bitumen 80/100 has a penetration between 80 and 100 while this value is attained at 25 degrees Celsius and with a 100g load that is applied for a period of five seconds. This range shows that Bitumen 80/100 is of a semi-solid nature and can thus be used across a very broad spectrum.

Properties of Bitumen 80/100

Bitumen 80/100 exhibits several key properties that contribute to its performance and suitability for various applications:

Consistency and Workability: Based on the penetration value, it is correctly termed as Bitumen 80/100, which has a moderate penetration value between 80 and 100 and provides a good consistency that makes it neither too soft for workability when used in constructions or during application processes.

Temperature Susceptibility: Bitumen 80/100 is a type of bitumen material that shows the property of being temperature sensitive. This is the ability to flow or gain a certain viscosity when heat is applied or become very rigid when cold. At high temperatures, it is more pliable than it is at lower temperatures, where it has greater stiffness characteristics and is not easily doable.

Adhesion and Cohesion: Bitumen is characterized by good, notable adhesive properties, which will help it easily stick to various construction materials, such as aggregates and reinforcement materials. It also boasts good cohesive strength, which helps to achieve the formidable stability and strength of the bituminous mixture.

Aging resistance: there are two types of aging that may be experienced by bitumen; these include oxidation aging and hardening aging. Medium aging resistance is demonstrated for bitumen 80/100. Therefore, they are used in areas that demand long endurance.

Water Resistance: Bitumen 80/100 has a good level of water resistance, and it is suitable for waterproofing and as a comprehensive material for highway construction, especially in regions with higher humidity or high rates of precipitation.

The properties mentioned above, coupled with the bitumen that has got the right turn of consistency, make it qualify to be used for the following purposes.

Applications of Bitumen 80/100

Bitumen 80/100 finds extensive use in various construction projects and applications, including:

Road Construction

Bitumen 80/100 is primarily used for the construction of roads as it is used for the preparation of asphalt mix in paving.

This works as a binder in the construction of road tracks and layers required for paving surfaces, flocks, tanks, bridges, and other structures. It is also worth noting that it has the right density and workability for the production of hot mix asphalt (HMA), and therefore, it can be mixed well, compacted, and applied appropriately. Further, client specifications and standard tests indicate that the incorporation of Bitumen 80/100 affords moderate resistance to rutting as well as to crack formation, which are essential factors in the resilience and sustainability of the pavements.

Roofing and Waterproofing

It is mainly found in the manufacturing of roofing felt and other waterproofing products like waterproofing sheets. It has excellent adhesion characteristics that enable the bond with reinforcing materials like fiberglass or polyester mat, which contributes to the roofing system’s strength and permeability resistance. Considering their effectiveness in preventing water from penetrating through buildings, they are used to protect structures from moisture and other environmental factors.

Sealants and Coatings

Bitumen 80/100 can be used to produce various sealants and coatings, including joint sealants for concrete pavements, protective coating for underground structures, and waterproofing coatings for foundations and basements among others. These properties of acrylic renders make it ideal for use in specific applications since it is able to flex with the building structure and resist water and other elements.

Maintenance and Repair

It is also used for maintenance and rehabilitation works to be carried out on various infrastructures, be it newly constructed or those that have been existing. It can be applied to crack sealing, pothole repair, and surface treatments, that is, enhancement of the serviceability of the road and pavement to reach satisfactory levels that will guarantee a safe and comfortable drive.

In conclusion, this subject provides best practices for working with Bitumen 80/100:

To ensure optimal performance and safety when working with Bitumen 80/100, it is essential to follow best practices and industry guidelines:

Handling and Storage

It is recommended that Bitumen 80/100 be stored in appropriate containers or tanks with proper protection from moisture, impurities, and high temperatures.

Proper storage: Store products with proper handling instructions that explain the proper PPE to use, including heat-resistant gloves, safety glasses, and respiratory protection, if needed.

Storage at recommended temperatures will guarantee consistency in viscosity and reduction in the degradation process.

Safety Considerations

As the temperature of the bitumen increases, it gives out toxic fumes and other dangerous vapors resulting from the evaporation of the solvents. Inadequate and low circulation of air in any environment should be supplemented by proper ventilation, and upper respiratory protection should be worn while in confined spaces.

Bitumen is an inflammable material and, at the same time, has side effects when it is in contact with the skin. Some recommended protective gear that should be worn by individuals who handle hot bitumen include heat-resistant gloves and covering garments such as coveralls.

Comply with all necessities set down under safety concerns within your geographical location or vocation.

Application Techniques

Concerning road construction, factors such as mixing, compaction, and use temperature for the mixture should be adhered to in order to realize the required workability and performance.

Regarding its use in roofing and waterproofing, adhere to methods of application, as well as temperature and reinforcement materials recommended by the manufacturer.

Bitumen 80/100 should be used as a sealant or coating for its recommended thickness and temperature control after preparing the surfaces properly.

Quality Control and Testing

It is necessary to perform quality control testing with frequency to assess whether the Bitumen 80/100 satisfies the penetration value with other performance characteristics.

Some of the tests that need to be conducted include penetration, softening point, and viscosity tests if the quality of the bitumen needs to be checked.

Adhere to best practices and put in place quality control measures to track and ensure that the project has met standard regulatory measures and other specifications.

So, by following all these best practices, construction professionals can get the optimum utilization of Bitumen 80/100 in order to bring improved safety, higher quality, and better performance for the longer term for the construction projects.

Case Study: Identification of Bitumen 80/100 In Road Construction

As for usage, it is necessary to explore the practicality of Bitumen 80/100 in the construction industry, particularly in the production of roads.

Project Overview

One of the most significant road construction involved the extension of 20 miles of a new paving surface that is situated in an area characterized by relative differences in both summer and winter temperatures. The project requirements that the asphalt mixture had to meet included that the mixture had to be of high and long-standing strength as it was to handle intensive traffic loading without rutting or cracking.

Challenges

Traffic Loads: The new highway section would cat; this is the area likely to experience high traffic of trucks, hence the need for an asphalt mixture that can meet loads as well as has high resistance to permanent deformation or rutting.

Durability: It was necessary to provide pavement with high eccentric strength, devoid of cracks and aging for a long period of time, and with minimum requirements for the frequency of repairs within the frame of its service time.

Construction Efficiency: When employed in or on infrastructure projects, the asphalt mixture must possess the right workability for easy mixing, compaction, and application.

Solution

To tackle these challenges, the project team made the following efficacious decisions: To use the Bitumen 80/100 for the production of the asphalt mixture. The specific properties of Bitumen 80/100 that made it suitable for this project include:

Balanced Consistency: The selected penetration value range of 40 to 60 allowed the mixture to have a desirable level of cohesiveness that was helpful during pavement construction yet offered enough stiffness to prevent the mixes from ruts under intense traffic loads.

Moderate Aging Resistance: On this aspect, it was found that the aging resistance of Bitumen 80/100 was moderate, thus allowing for enough durability of the asphalt mixture while minimizing the cracking and deterioration.

Adhesion and Cohesion: In this regard, Bitumen 80/100 provided good adhesion and cohesive strength, which were critical for the interaction between the bitumen and aggregates in the asphalt mixture, as well as overall performance.

Implementation and Results

Conducting laboratory tests and optimizing the mix design, it was concluded that the asphalt mixture based on Bitumen 80/100 complied with all requirements and could be used in construction. The implementation phase involved the following steps: The implementation phase involved the following steps:

Procurement and Quality Control: Suppliers from whom the materials and equipment for the project were imported were reputable stores, and quality control measures were put in place to ensure that only the required quality of the Bitumen 80/100 was used for the project. Measures such as penetration tests and viscosity measurements were carried out for regular tests to see if they possessed the right properties.

Asphalt Plant Operations: The asphalt plant was first set to match the characteristics of the Bitumen 80/100 mix type and, secondly, was fine-tuned for the specific needs of this mixture. It was likewise controlled, striving to be at the best temperature for workability and desired homogeneity of mixtures.

Paving and Compaction: The asphalt mixture was then taken to the sites where it was compacted into the desired depths using suitable paving equipment. Measures taken include control of compaction, which was done in a systematic manner. A strategy of getting the right density and uniformity was used to bring the best performance out of the soil and ensure better durability.

Quality Assurance Testing: During and after construction, extensive quality assurance testing was conducted, including core sampling and laboratory analysis. This ensured that the finished pavement met the project’s specifications and performance requirements.

Conclusion

Bitumen 80/100 is one of the popular types, and it is widely used in most construction structures, especially in the construction of roads, as construction material for roofs, and mostly in waterproofing. It can be rated as quite a versatile material owing to its fairly good constancy and workability, as well as moderate cold check sensitivity.

A number of directions, such as modification of polymers, implementation of recycling programs, use of warm mix asphalt technologies, and the search for bio-based modifiers, are some of the new directions in the development of the construction sector, which have great potential for enhancement of the performance characteristics of the products derived from Bitumen 80/100 and reducing the adverse effects on the environment.

By maintaining these developments and being willing to change, the specialists in the construction industry will be in a position to optimize the effectiveness of using Bitumen 40/ 60 as part of the sustainable development goals of construction.

Thus, it is proposed to consider Bitumen 80/100 as one of the top priorities and one of the most effective materials for construction, as the analysis of the results provided has demonstrated satisfactory performance characteristics, workability, and versatility. This way, adopting high standards of practice by embracing quality assurance and educational activities in the industry, this buoyant bitumen grade holds a critical key to manifesting bold and enduring construction structures projects that deliver high-value performance and sustainability.