Fuel Oil

Table of Contents

Fuel oil is one of the petroleum hydrocarbons that is obtained during the refining process of crude oil after ether, gasoline, and lamp oil. because of its color (black), it is called black oil. This material is the cheapest fuel for bathroom furnaces and bakeries, diesel engines, and some power plants.

Some fuel oils include heavy fuel oil, marine fuel oil (MFO), bunker fuel, furnace oil, gas oil (Gasoil), heating oil, diesel fuel, and etc.

Types of Fuel Oil (produced in Iran)

According to the National Broadcasting and Refining Company, mazut, which is known as fuel oil, is produced in 3 different types in Iran;

Fuel oil 180 and 230, which consists heavier than petroleum gas, and its constituent compounds are mainly heavy hydrocarbons found in the residue of crude oil distillation, which, depending on the use, is adjusted to viscosity using light oil cuts and used as heavy fuel. It is used by fixed and mobile diesels and industries whose burners are designed for their combustion system and can use this product.

Fuel oil 280 and 380, which is the residual product of distillation towers, is viscosity adjusted using lighter cuts and is supplied as fuel. The latter grade with the percentage of its compounds gives a suitable calorific value to the fuel. The amount of metals in this type of fuel oil does not cause problems in consumer systems, therefore it is used as a fuel in industries and power plants that use medium fuel oil in their combustion system.

Heavy fuel oil is heavy residue resulting from the distillation of crude oil in distillation towers, which mainly does not need to be mixed with light products to adjust the viscosity and can be supplied directly. Appropriate sulfur percentage and good calorific value are the characteristics of this fuel. Heavy fuel oil is used in industries and power plants that use heavy fuel in their fuel system.

Fuel oil 180cst

Fuel oil 180cst is a specific grade of heavy fuel oil (HFO) that is widely used in various industrial applications, especially in the maritime and energy sectors. In this article, we will delve into the specifications, production process, structure, and usages of Fuel Oil 180cst to provide a comprehensive overview of this essential energy product.

Specifications of Fuel Oil 180cst

Fuel Oil 180cst, also known as Bunker Fuel or Residual Fuel Oil, is characterized by its viscosity, which is measured in centistokes (cst). The number 180 indicates the maximum viscosity of the oil at 50 degrees Celsius. This specification makes it a relatively thick and viscous fuel, compared to lighter fuel oils.

Key specifications include:

- Viscosity: 180cst at 50°C

- Density: Typically around 0.96 to 0.99 kg/l at 15°C

- Sulphur content: Varies according to regional regulations, but usually ranges from 1.0% to 3.5% by weight

- Flash point: Usually above 60°C

- Pour point: The temperature at which the fuel will cease to flow, typically above 0°C

Production Process of Fuel Oil 180cst

Fuel Oil 180cst is produced during the refining process of crude oil. It is one of the heavier products obtained from the fractional distillation of crude oil, following lighter fractions like gasoline, diesel, and kerosene.

The production process involves several stages:

- Distillation: Crude oil is heated, and various hydrocarbon fractions are separated based on their boiling points.

- Conversion: Heavier fractions are converted into lighter products through processes such as cracking and coking.

- Treatment: The residual oil undergoes further treatment to remove impurities and improve quality, including desulfurization to reduce the sulfur content.

Structure of Fuel Oil 180cst

Fuel Oil 180cst consists of complex hydrocarbon chains, primarily aliphatic, aromatic, and naphthenic hydrocarbons. Its structure is less uniform compared to refined fuels, given that it is a residual product comprising the heavier molecules left after lighter fractions have been removed.

Usages of Fuel Oil 180cst

Fuel Oil 180cst is primarily used as a bunker fuel for large ships and vessels, including cargo ships, tankers, and cruise ships. Its high energy content and relatively lower cost make it a preferred choice for the maritime industry. Additionally, it is used in power plants and industrial boilers where high-viscosity fuel can be handled and burned efficiently.

Environmental regulations, such as those enforced by the International Maritime Organization (IMO), are pushing for lower sulfur content in fuel oils to reduce harmful emissions. As a result, the maritime industry is gradually shifting towards using low-sulfur fuel oils or alternative fuels to comply with these regulations

Grand Petroleum Company offers Fuel Oil in bulk packaging, ready to meet domestic and international market demands. For further details or to place an order, please contact the Grand Petroleum Sales Department.

Fuel Oil 230cst

Fuel oil, a byproduct of crude oil refining, plays a crucial role in various industrial applications. Among the different grades, Fuel Oil 230cst and Fuel Oil 180cst are widely used due to their viscosity and energy content. Let’s delve into the specifics of Fuel Oil 230cst and compare it with Fuel Oil 180cst, highlighting their specifications, production processes, structures, and usages.

Specifications of Fuel Oil 230cst

Fuel Oil 230cst, also known as Heavy Fuel Oil (HFO) or Residual Fuel Oil (RFO), is characterized by its kinematic viscosity, which is measured at 230 centistokes (cst) at 50 degrees Celsius. This specification indicates the thickness or resistance to flow of the oil. The higher the cst number, the more viscous the fuel oil. The viscosity of Fuel Oil 230cst makes it suitable for larger, slower-speed engines and boilers that can handle its flow characteristics.

Other specifications include its sulfur content, flash point, pour point, calorific value, and density. These parameters are crucial for determining the fuel’s suitability for different applications and its environmental impact.

Production Process of Fuel Oil 230cst

The production of Fuel Oil 230cst involves the refining of crude oil. During the distillation process, lighter hydrocarbons are separated, and the heavier fractions are collected as residue. This residue undergoes further treatment, including blending with lighter fractions, to achieve the desired viscosity and quality. The production process is carefully monitored to ensure compliance with international standards and environmental regulations.

Structure and Usage of Fuel Oil 230cst

Fuel Oil 230cst is a complex mixture of hydrocarbons, including paraffins, cycloparaffins, aromatics, and asphaltenes. Its structure determines its properties, such as energy content and combustion behavior.

This fuel oil is predominantly used as bunker fuel for ships, fuel for large industrial boilers, and in power generation plants. Its high energy content and relatively lower cost make it an attractive choice for these applications, provided that the equipment is designed to handle its viscosity and combustion characteristics.

Comparison with Fuel Oil 180cst

Fuel Oil 180cst has a lower viscosity than 230cst, measured at 180 centistokes at 50 degrees Celsius. This lower viscosity makes it easier to pump and handle, allowing for use in a wider range of engines and boilers, including those with higher speed and lower capacity. Additionally, Fuel Oil 180cst may require less preheating compared to 230cst, which can lead to operational efficiencies.

In terms of usage, both grades are used in marine, industrial, and power generation sectors. However, the choice between the two often comes down to the specific requirements of the equipment, operational considerations, and cost.

While both fuels have similar production processes and structures, the specifications of Fuel Oil 180cst might be slightly different, with potentially lower sulfur content and different flash and pour points, which can impact environmental emissions and the handling of the fuel.

In conclusion, Fuel Oil 230cst and 180cst serve critical roles in the energy sector. While they share similarities in their production and structure, their differences in viscosity lead to distinct applications and handling requirements. Understanding these nuances allows industry professionals to make informed decisions about fuel selection based on performance, cost, and environmental considerations.

Fuel oil, a byproduct of crude oil refining, plays a crucial role in various industrial applications. Among the different grades, Fuel Oil 230cst and Fuel Oil 180cst are widely used due to their viscosity and energy content. Let’s delve into the specifics of Fuel Oil 230cst and compare it with Fuel Oil 180cst, highlighting their specifications, production processes, structures, and usages.

For further details or to place an order, please contact the Grand Petroleum Sales Department.

Fuel Oil 280cst

Fuel oil 280cst Specification

280 CST Fuel Oil Export Quality | |||

Test | Unit | Specification | Test Method |

Density @ 15DC | KG/M^3 | MAX 970 | D-1298 |

Kinomatic Viscosity @ 50 DC | CST | MAX 280 | D-445 |

Visco. [email protected] | SECS | MAX 2500 | Calculated |

Pour Point | DC | Max 24 | D-97 |

Flash Point | DC | MIN 65 | D-93 |

Sulphur Total | WT% | MAX 3.5 | D-1552 |

Carbon Residue (Conradson) | WT% | MAX 15 | D-189 |

Ash | WT% | MAX 0.05 | D-482 |

Water | VOL% | MAX 0.5 | D-1796 |

Colorific Value (Higher) | MJ/KG | MIN 41.8 | Calculated |

Fuel Oil 380cst

Fuel Oil 380cst plays a critical role in the global energy infrastructure, particularly in maritime transportation and industrial power generation. While it shares similarities with other heavy fuel oils, its specific characteristics and requirements make it distinct. As environmental regulations become more stringent, the production and use of Fuel Oil 380cst are likely to evolve, with a focus on reducing sulfur content and other impurities to minimize the environmental impact of its combustion.

Specifications of Fuel Oil 380cst

Fuel Oil 380cst is a heavy fuel oil with a viscosity of 380 centistokes at 50 degrees Celsius. Its high viscosity means it is thicker and flows more slowly compared to fuels with lower viscosities. The specifications for Fuel Oil 380cst are often determined by international standards such as ISO 8217, which sets out the requirements for marine fuels. Key specifications include:

- Kinematic viscosity: The primary characteristic, measured in centistokes.

- Density: Typically higher than lighter fuel oils, affecting the energy content and storage requirements.

- Sulfur content: Limited by environmental regulations, affecting emissions when the fuel is burned.

- Flash point: The minimum temperature at which the fuel can vaporize to form an ignitable mixture in air.

- Carbon residue: Indicates the tendency to form deposits and sludge in the fuel system.

- Water and sediment content: Impurities that can affect combustion and lead to maintenance issues.

380 CST Fuel Oil Export Quality | |||

Test | Unit | Specification | Test Method |

Density @ 15DC | KG/M^3 | MAX 990 | D-1298 |

Kinomatic Viscosity @ 50 DC | CST | MAX 380 | D-445 |

Pour Point | DC | Max 32 | D-97 |

Flash Point | DC | MIN 65 | D-93 |

Sulphur Total | WT% | MAX 3.5 | D-1552 |

Carbon Residue (Conradson) | WT% | MAX 15 | D-189 |

Ash | WT% | MAX 0.15 | D-482 |

Water | VOL% | MAX 1.0 | D-1796 |

Colorific Value (Higher) | MJ/KG | MIN 41.7 | Calculated |

Structure and Production Procedure

Fuel Oil 380cst is a complex mixture of hydrocarbons derived from the refining process of crude oil. The structure of the fuel oil is not a single compound but rather a blend of various hydrocarbon chains, including alkanes, cycloalkanes, and aromatic hydrocarbons.

The production of Fuel Oil 380cst involves several steps:

- Distillation: Crude oil is heated and separated into fractions based on boiling points in a distillation column. The heavier fractions are the precursors to heavier fuel oils.

- Conversion: Heavier fractions undergo conversion processes such as cracking to break down larger molecules into more useful sizes.

- Blending: Various fractions are blended to achieve the desired viscosity and specifications. Additives may be introduced to enhance properties such as stability and combustion performance.

- Treatment: The blended fuel is treated to remove contaminants like sulfur compounds to meet environmental regulations.

Difference Between Fuel Oil 380cst and 180cst

The primary difference between Fuel Oil 380cst and 180cst is their viscosity. Fuel Oil 180cst is less viscous, meaning it flows more easily at a given temperature. The lower viscosity of 180cst fuel oil typically translates to a lower density and sometimes a lower sulfur content, making it slightly more refined and cleaner burning than the 380cst grade. The choice between the two often depends on the requirements of the engine or furnace, with some systems designed to operate more efficiently on a specific grade.

Industry Use

Fuel Oil 380cst is predominantly used in the maritime industry as bunker fuel for large ships and vessels. Its high energy content and relatively lower cost compared to lighter fuels make it a preferred choice for long-distance shipping. It is also used in industrial settings for heating and power generation, particularly in facilities with equipment designed to handle its high viscosity and density.

Fuel Oil m100

Structure

Mazut is a low-quality fuel oil that is heavy. This heavy fuel oil is used for heating homes. Although it is called “waste oil” heaters or “waste oil” furnaces, fuel oil m100 is the product of heavy oil from the residue of distillation towers, which is adjusted and sold as fuel. The composition of the percentage of hydrocarbons gives a suitable heating value to fuel and the amount of metals present does not cause problems in the consumer systems.

Application

Almost Heavy fuel oil m100 is suggested as a fuel in industries in their combustion system.

Note: Heating oils

Heating oils are the kind of fuel oil that is known. Heating oil is used as home heating oil. Although the use of petroleum products for space heating is very important, this use changes a lot depending on the location and weather conditions.

In recent years, the need for heating oils has decreased relatively, because the consumption of LPG (liquefied petroleum gas, which is used for domestic heating and cooking) has increased.

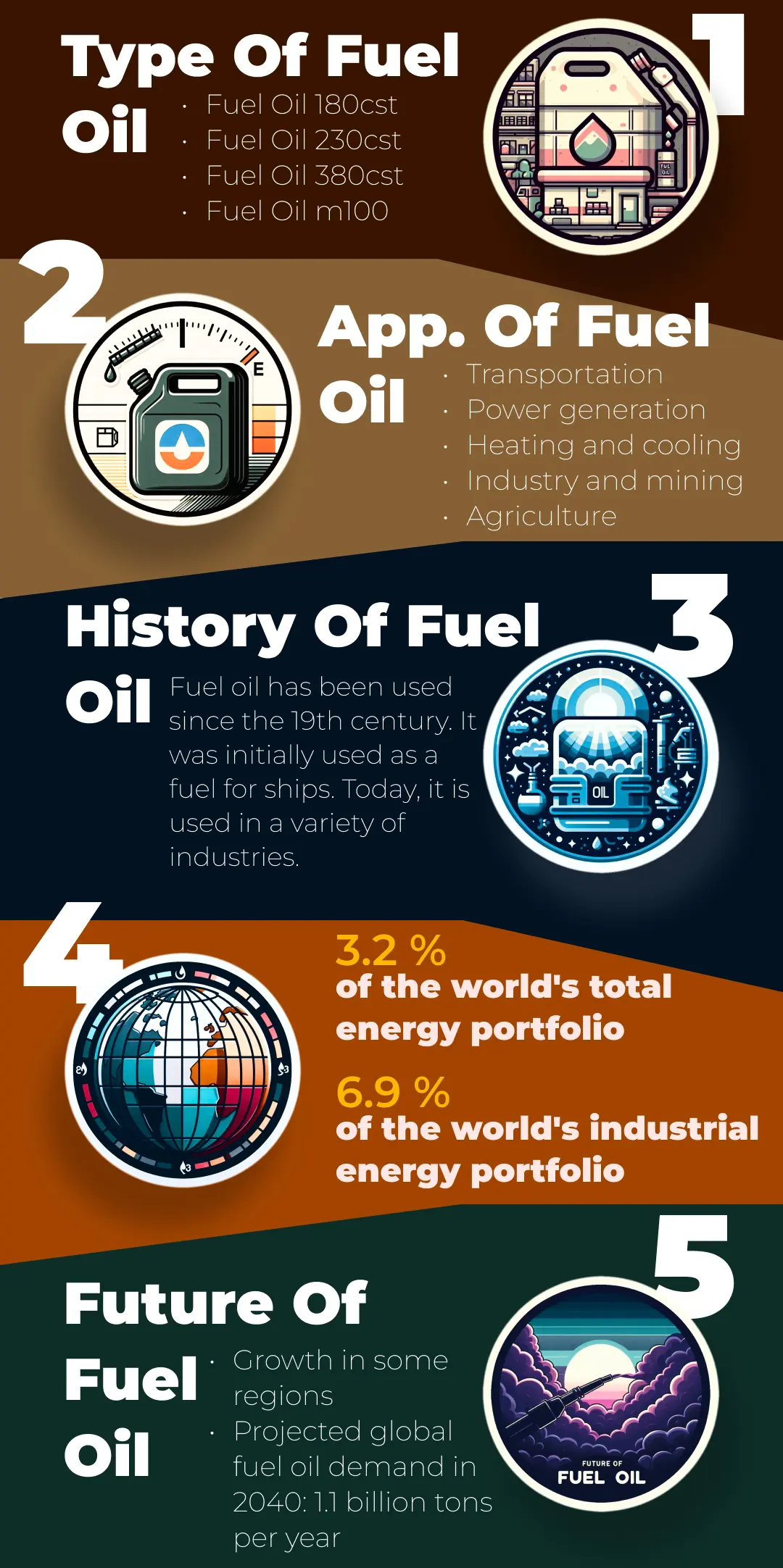

Fuel Oil Infographic 📊⚡⚡

For further details or to place an order, please contact the Grand Petroleum Sales Department.