Why bulk packaging for petrochemicals?

Bulk packaging is widely used in the petrochemical industry to transport large quantities of liquid or solid materials. The primary purpose of bulk packaging is to reduce the cost of transportation and improve the efficiency of logistics. It also allows for the safe and secure transportation of hazardous materials, as specialized containers are designed to prevent leaks and spills. Other benefits of bulk packaging include the reduction of packaging waste, as fewer containers are required, and the ability to load and unload materials more quickly. Bulk packaging is a cost-effective and environmentally friendly solution for transporting petrochemical products.

The procedure of bulk packaging:

Bulk packaging and loading of bitumen onto vessels is a specialized process that requires careful handling and attention to safety due to the product's high viscosity and temperature sensitivity. Bitumen, also known as asphalt, is a sticky, black, and highly viscous liquid or semi-solid form of petroleum used primarily for road construction and waterproofing. Here is a detailed explanation of the procedure:

Heating the Bitumen: Before packaging or loading, bitumen must be heated to reduce its viscosity and make it easier to handle. This is often done in large storage tanks equipped with heating coils to maintain the bitumen at a temperature typically between 100°C and 200°C (212°F to 392°F), depending on the grade of bitumen.

- Bulk Packaging: For packaging into bulk containers, the heated bitumen is transferred from storage tanks to insulated containers such as drums, bags, or flexible totes. These containers are designed to maintain the temperature of the bitumen during transportation. The filling process involves the use of a loading arm or a bitumen pump that can withstand high temperatures.

- Transport to Port: Once packaged, the containers are transported to the port using heat-retaining transport methods, such as insulated trucks or railcars, to ensure the bitumen remains fluid.

- Port Storage: At the port, the bitumen containers are stored in a designated area, typically with facilities to maintain the temperature of the product until it is ready to be loaded onto the vessel.

- Vessel Preparation: Bulk vessels used for transporting bitumen are equipped with heating systems to keep the cargo liquid during sea transport. The vessel's tanks are preheated prior to loading to prevent the bitumen from solidifying.

- Pipeline Preparations: The loading pipelines at the port are also preheated to ensure smooth flow of the bitumen. These pipelines are insulated and equipped with heating systems to maintain the product's temperature.

- Loading Operation: The actual loading process begins with connecting the vessel to the port's loading arms or hoses. The bitumen is then pumped from the port's storage tanks through the preheated pipelines and into the vessel's tanks. The flow rate and temperature are closely monitored to ensure a safe and efficient loading process.

- Safety Measures: Throughout the loading process, strict safety protocols are followed. This includes monitoring for leaks, maintaining proper temperature control, and ensuring proper ventilation to avoid the buildup of fumes.

- Documentation and Sealing: After loading, the vessel's tanks are sealed, and all necessary documentation is completed, including the bill of lading, certificate of quality, and certificate of quantity. These documents are essential for the receiving party to confirm the shipment's compliance with specifications.

- Departure: Once the loading is finished, and all safety checks are complete, the vessel is cleared for departure. The bitumen is then transported to its destination, where it will be unloaded using a similar process in reverse.

The Optimal Solution for Bitumen Transportation: 180kg New Steel Drums

In the industrial sector, the transportation and storage of bitumen are of paramount importance. Bitumen, a viscous, black, and sticky form of petroleum, is commonly used in road construction and waterproofing applications. Ensuring its safe packaging is crucial, and that's where steel drums come into play.

The new steel drum, particularly the 180kg and 150kg sizes, has emerged as a reliable and efficient solution for bitumen packaging.

The Specification of Drums for Bitumen Packaging

When it comes to the specification of drums for bitumen packaging, the industry has standardized certain sizes to optimize transportation and storage. The most common sizes are 180kg and 150kg new steel drums. These drums are designed to withstand the heavy weight and high temperatures of bitumen while ensuring no leakage or contamination occurs during transit.

The 180kg new steel drum

typically has dimensions that align with international shipping standards, making it an excellent choice for exporting bitumen. It is constructed from high-quality steel and coated with materials that resist corrosion. The drum's interior is often treated with a special coating to prevent the bitumen from adhering to the steel, ensuring easy unloading.

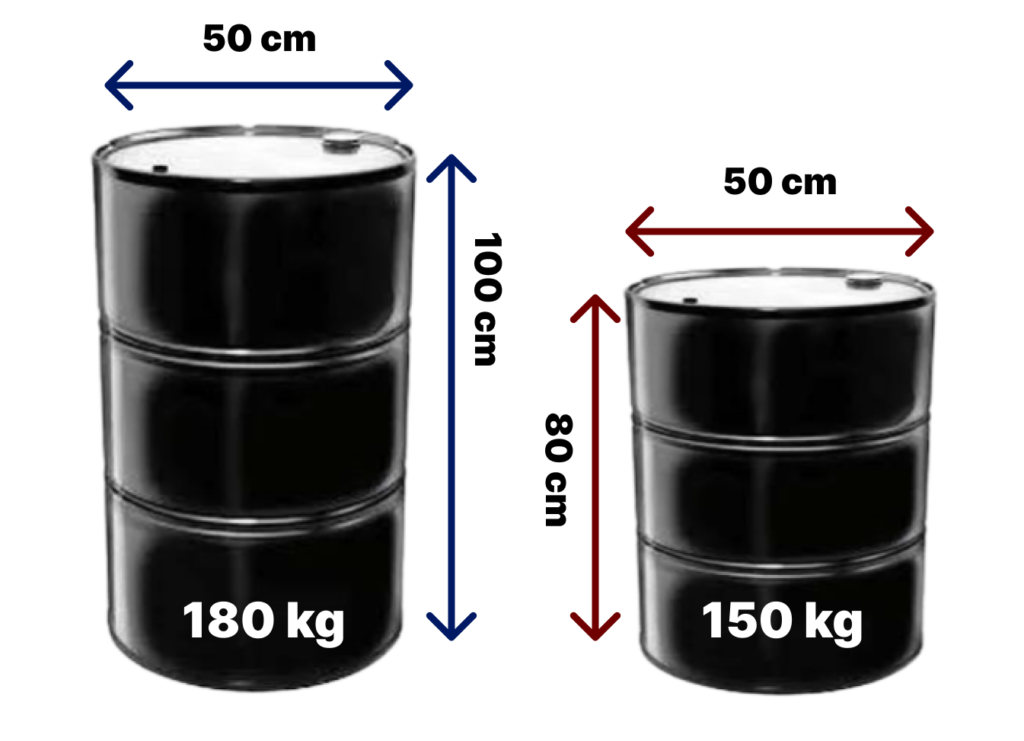

The 180 kg Drum Dimension / Size |

Height: 98 ± 2 (cm) |

Diameter: 50 (cm) |

Body Thickness: 0.6 ± 0.02 (mm) |

Top/Base Thickness: 0.6 ± 0.02(mm) |

Net Weight: 182 ± 2 (kg) |

Gross Weight: 192 ± 2 (kg) |

Empty Drum Weight: 9.5 ± 1 (kg) |

The 150kg drum, while slightly smaller, still provides ample protection and storage capacity for bitumen. It shares similar construction features with the 180kg drum, including the corrosion-resistant coating and interior treatment.

The 150 kg Drum Dimension / Size |

Height: 86 ± 2 (cm) |

Diameter: 50 (cm) |

Body Thickness: 0.6 ± 0.02 (mm) |

Top/Base Thickness: 0.6 ± 0.02(mm) |

Net Weight: 150 ± 2(kg) |

Gross Weight: 158 ± 2(kg) |

Empty Drum Weight: 8.5 ± 1 (kg) |

Both sizes of drums come with secure sealing options, such as gaskets and locking rings, to further prevent leaks and maintain the quality of the bitumen during transport.

Production Process of New Steel Drums

The production process of new steel drums for bitumen involves several key steps to ensure they meet industry standards and safety requirements. First, high-grade steel is cut and rolled into cylindrical shapes. The edges are then welded together to form a solid barrel. The bottom and top are added and sealed to create a closed container.

After the basic shape is formed, the drums undergo a series of treatments to enhance their durability and performance. This includes degreasing, phosphating, and painting, which provides a protective layer against the elements and potential chemical reactions with the stored bitumen.

Standard Size and Benefits of 180 kg and 150 kg Drums

The standard size of the 180 kg and 150 kg drums is not arbitrary. These sizes have been carefully selected to balance the ease of handling and the efficiency of space utilization in transportation vehicles. The dimensions of these drums are optimized to fit into containers and trucks, allowing for maximum utilization of space and reducing shipping costs.

Using the 180kg and 150kg new steel drums for bitumen packaging offers numerous benefits, including:

- Safety: The robust construction of steel drums ensures that bitumen is safely contained during transportation and storage, reducing the risk of spills and accidents.

- Quality Preservation: The special interior coating of the drums prevents contamination and maintains the quality of the bitumen, which is essential for its intended applications.

- Cost-Effectiveness: The standard sizes of these drums allow for efficient packing in shipping containers, reducing transportation costs and making them a cost-effective packaging option.

- Reusability: Steel drums can be cleaned and reused, which is not only economical but also environmentally friendly.

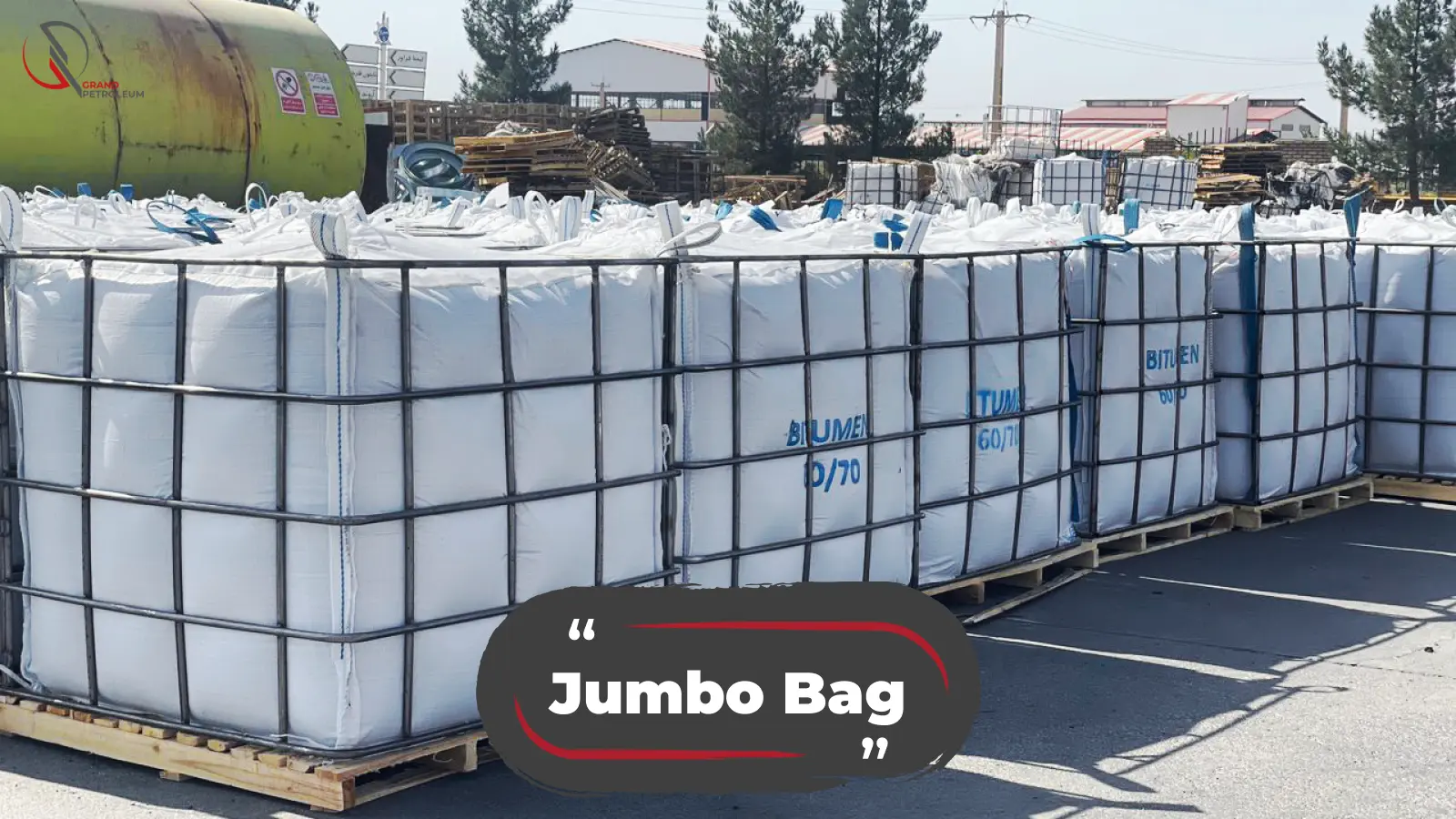

Jumbo Bag Packaging: An Efficient Solution for Transporting Bitumen

In the petrochemical industry, the transportation and storage of products like bitumen require packaging solutions that are robust, cost-effective, and efficient. Jumbo bags, also known as FIBCs (Flexible Intermediate Bulk Containers), have emerged as an optimal choice for handling such materials. This article explores the world of jumbo bag packaging, focusing on its application for carrying bitumen, the various types available, and the circumstances under which they are most beneficial.

What is a Jumbo Bag?

A jumbo bag is a large, flexible container designed for storing and transporting dry, flowable products, including granules, powders, and in some cases, semi-solids like bitumen. Made from woven polypropylene (PP) or polyethylene (PE) fabrics, these bags can typically hold anywhere from 500 to 2000 kg of product. Jumbo bags are equipped with loops for lifting, which makes them easily maneuverable by forklifts or cranes.

Why use Jumbo Bag for Petrochemicals Such as Bitumen?

Bitumen, a viscous and sticky form of petroleum, is widely used in road construction and roofing. Its handling poses unique challenges due to its semi-solid state and temperature sensitivity.

Jumbo bags offer several advantages for bitumen packaging:

Safety: They are strong and durable, reducing the risk of spills or leaks during transportation and storage.

Cost-Efficiency: Compared to traditional drums or tankers, jumbo bags are more economical, both in terms of material costs and the expenses associated with handling and transport.

Space Optimization: Jumbo bags can be stacked and occupy less space than other containers, maximizing storage and shipping efficiency.

Customization: They can be tailored to specific requirements, such as resistance to high temperatures or UV protection.

Environmentally Friendly: Jumbo bags are reusable and recyclable, reducing environmental impact.

Types of Jumbo Bags that might be used for Bitumen:

Bitumen Bag Meltable: These bags are designed to be directly melted into the bitumen mix. They are often made from a type of polymer that can be melted at high temperatures without leaving any residue.

High-Temperature Resistant Bags: Bitumen is typically handled at high temperatures (usually around 100-200°C). These bags are made from materials that can withstand such temperatures without degrading. They may be constructed from high-grade polypropylene or other synthetic materials that offer heat resistance.

Lined Bags: Some jumbo bags for bitumen come with an inner lining to prevent the bitumen from sticking to the sides of the bag and to provide an additional layer of protection against leaks. The lining could be made from materials like aluminum or other heat-tolerant plastics.

Conductive Bags (Type C): In situations where static discharge could be a hazard, conductive bags may be used. These are designed to control electrostatic charges by grounding.

Dissipative Bags (Type D): These bags are made from anti-static fabric that dissipates static charge without the need for grounding.

Materials used for manufacturing these bags are generally variants of woven polypropylene, which is durable, strong, and sometimes treated or coated for specific applications like heat resistance or static dissipation.

Jumbo bags are preferred in what countries

As for the usage of jumbo bags for bitumen across different countries, they are widely used in countries that have significant road construction projects or have large petroleum industries. This includes countries like:

United States

Canada

- China

- Russia

India

Countries in the Middle East, such as Saudi Arabia and Iran

Australia

Brazil

- European countries with robust infrastructure projects

The choice of jumbo bag and material would depend on the specific requirements of the bitumen handling process, including transportation, storage, and the final application of the bitumen. Regulations, safety standards, and environmental considerations also play a critical role in determining the type of jumbo bag used in different countries.

In what circumstances Jumbo Bags are used:

Jumbo bags are used for bitumen in several circumstances:

- When bitumen needs to be transported over long distances and the cost of traditional methods is prohibitive.

In regions where access to specialized bitumen tankers is limited.

For smaller or medium-scale projects where the quantity of bitumen does not justify the use of a full tanker.

When there is a need for temporary storage of bitumen at the job site before application.

In scenarios where the bitumen must be transported to remote or difficult-to-access locations.

Dimensions and Size of Jumbo Bags:

The dimensions of a standard jumbo bag are usually around 90 cm x 90 cm x 120 cm (35 in x 35 in x 47 in), with a typical capacity of about 1 cubic meter or 1 tonne (1000 kg), but they can come in various sizes, some smaller and many larger, with capacities ranging from 500 kg to 2000 kg or more.

When it comes to loading Jumbo Bags into Containers:

A 20-foot container can typically hold about 10 standard pallets in one tier, so if each pallet carries one jumbo bag, you could potentially load 10 jumbo bags. However, when not using pallets and depending on the size of the bags and how they are packed, the number might increase to 20 or more.

A 40-foot container can usually hold up to 20-25 standard pallets in one tier, which would equate to 20-25 jumbo bags if each pallet carries one bag. Without pallets, and depending on the size of the bags and the packing method, the number might increase to 40 or more.

Please note that these are just rough estimates, and the actual number of jumbo bags that can fit within a container can vary based on the exact dimensions and weight of the bags, the packing method used, and any weight limitations for the transport vehicle or container. It's important to ensure that the load is secure and within the legal weight limits for transport.

Flexi Tank: A Flexible Solution for Bulk Liquid Transport

Flexi tanks, also known as flexi bags, is an elastic, supplementary cistern, made of special polymers and developed directly for six-meter containers (20-foot). They are a popular choice for transporting bulk liquids. Made from flexible, durable materials, these containers are designed to fit inside standard shipping containers, making them an ideal solution for transporting liquids in a cost-effective and efficient manner. This elastic container can have a different volume: from 10 to 24 cubic meters. A weight of load, that is transported in this capacity, is defined as 95% from product of transported liquid's density to volume of flexitank. Possible losses during loading and unloading are no more than 5%.

Sizes:

Flexi tanks come in a range of sizes, with capacities typically ranging from 16,000 to 24,000 liters. This flexibility allows companies to choose the size that best suits their specific requirements, whether they are transporting smaller or larger quantities of liquid.

In Which Countries Mostly Used:

Flexi tanks are used around the world, with a strong presence in countries that rely heavily on liquid imports and exports. Some of the countries where flexi tanks are commonly used include the United States, China, India, and various European countries.

Transport Sizes of Flexitanks for 20f Container

Weight and Volume in transport packing | Amount in the container | |||||||

Article | Net(kg) | Gross | Packing size | Volume (m3) | 20f | 20f | 40f | 40f |

Flexi tank | 40.25 | 43.7 | 1135*5*25*430 | 256 | 60 | 100 | 140 | 120 |

Steel pipe | 38.75 | 40.2 | 244*210*140 | 72 | 0 | 100 | 0 | 120 |

Partition | 10.5 | 10.7 | 2330*1480*16.5 | 57 | 0 | 100 | 0 | 120 |

Crinkled paper | 11.4 | 11.4 | 1400*(160*160*31.4) | 113 | 0 | 100 | 0 | 120 |

Total | 100.9 | 106.0 | 498 | |||||

Capacity and Dimensions:

The capacity and dimensions of flexi tanks can vary depending on the specific model and manufacturer. However, a standard flexi tank typically has a capacity of around 16,000 to 24,000 liters. The dimensions of a flexi tank are designed to fit inside a standard 20-foot shipping container, making it easy to transport and handle.

Different Types of Flexi Tank:

There are several different types of flexi tanks available, each with its own unique features and benefits. Some of the most common types include:

- single-use flexi tanks,

- multi-trip flexi tanks,

- and flexi tanks with heating pads for transporting temperature-sensitive liquids.

The process of filling flexi tanks with Bitumen:

Flexi tanks are filled with bitumen through a carefully controlled process to ensure the safe and efficient transportation of the product.

First, the flexi tank is inspected for any damage or defects that could compromise its integrity. Once cleared, the flexi tank is positioned in a secure location and the bitumen is heated to the appropriate temperature for pumping. The bitumen is then pumped into the flexi tank through a specially designed hose and nozzle system, taking care to avoid overfilling and ensuring that the tank is properly pressurized.

Throughout the filling process, the temperature and pressure of the bitumen are monitored to prevent any potential hazards. Once the tank is filled, it is sealed and prepared for transportation, maintaining the quality and integrity of the bitumen until it reaches its destination.

Advantages of Using This Kind of Packages:

There are several advantages to using flexi tanks for bulk liquid transport. One of the key benefits is their cost-effectiveness, as they are typically more affordable than traditional bulk liquid containers. Additionally, flexi tanks are lightweight and easy to handle, making them a convenient option for transporting liquids. They also offer a high level of safety and security, as they are designed to prevent leaks and spills during transport.

In conclusion, flexi tanks are a flexible and efficient solution for transporting bulk liquids. With a range of sizes and types available, they are well-suited for a wide variety of liquid products and offer numerous advantages for companies looking to transport liquids in a cost-effective and secure manner.