Bitumen, also known as asphalt or tar, is a versatile and crucial material used in various industries, from road construction to roofing. Proper storage and handling of bitumen are of paramount importance to ensure its quality and safety. In this comprehensive guide, we will explore the best practices for bitumen storage and handling to help you make the most of this valuable resource.

Understanding Bitumen

Before delving into storage and handling practices, let’s first understand what bitumen is. Bitumen is a viscous, black, and highly sticky substance obtained from crude oil refining. Its unique properties make it an ideal choice for road construction, waterproofing, and various industrial applications. Bitumen comes in different grades and forms, including penetration-grade bitumen and bitumen emulsions. Understanding the specific type of bitumen you are working with is crucial as it can impact storage and handling procedures.

Importance of Proper Storage

Proper bitumen storage is the cornerstone of ensuring its quality and performance in various applications. Bitumen is sensitive to temperature variations and exposure to air, so storing it correctly is vital. When bitumen is not stored properly, it can lead to oxidation, hardening, and loss of desirable properties, making it unsuitable for use.

Suitable Storage Containers

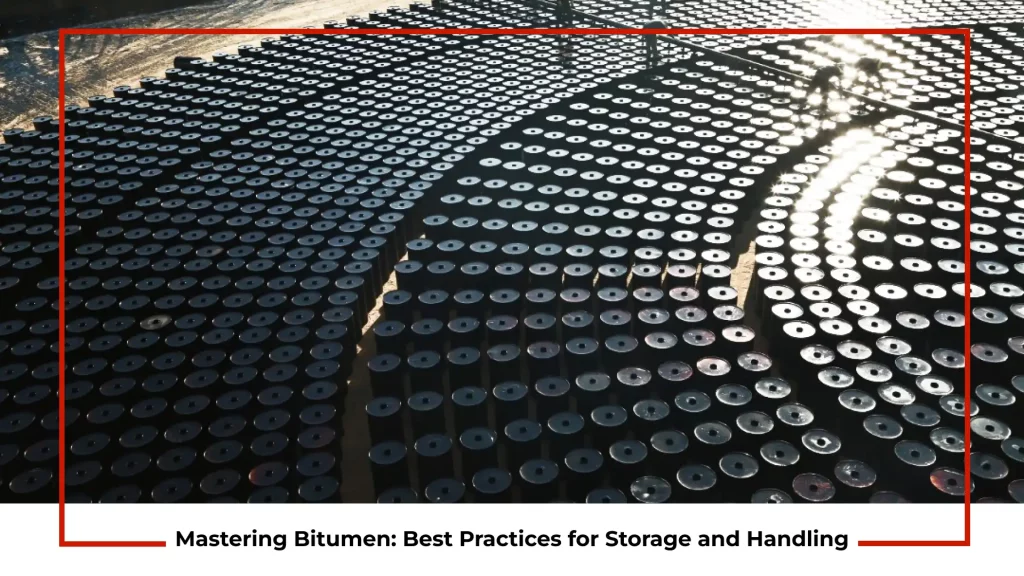

Selecting the right storage containers is the first step in ensuring the integrity of your bitumen. Bitumen should be stored in containers made of materials that are resistant to corrosion and can withstand high temperatures. Steel tanks and drums are commonly used for bitumen storage. These containers should be kept clean and free of any contaminants that could compromise the quality of the bitumen.

Temperature Control

Maintaining the appropriate temperature is crucial when storing bitumen. Bitumen should be stored at a consistent temperature to prevent it from becoming too viscous or too brittle. This can be achieved by using heating systems such as heating coils or electric heaters. It’s essential to monitor and control the temperature regularly to ensure it remains within the recommended range.

Handling Precautions

Handling bitumen requires careful attention to safety measures. Bitumen is hot when it’s transported and handled, so it can cause severe burns if it comes into contact with skin. Proper personal protective equipment (PPE) should be worn, including heat-resistant gloves and clothing. Spills and accidents should be addressed promptly to prevent injuries and environmental damage.

Transportation Guidelines

When transporting bitumen, it’s essential to follow specific guidelines to ensure safe and efficient delivery. Bitumen should be transported in dedicated tankers or containers designed for this purpose. These vehicles should be equipped with proper heating and insulation to maintain the bitumen’s temperature during transit.

Quality Control

Regular quality control checks are crucial for bitumen storage and handling. Periodically testing the bitumen’s properties, such as viscosity and penetration, can help identify any changes or degradation. If any issues are detected, corrective measures should be taken promptly to maintain the quality of the stored bitumen.

Environmental Considerations

Bitumen storage and handling can have environmental impacts if not managed responsibly. Spills and leaks can harm the environment and wildlife. It’s essential to have spill containment measures in place, such as bund walls and absorbent materials, to prevent any potential environmental damage.

Compliance with Regulations

Compliance with local and national regulations is paramount when it comes to bitumen storage and handling. Regulations may vary depending on your location and the specific industry you’re operating in. Ensure that your storage and handling practices adhere to all relevant laws and regulations to avoid legal issues and penalties.

In conclusion, mastering the best practices for bitumen storage and handling is essential to maximize its utility and maintain its quality. Understanding the properties of bitumen, choosing suitable storage containers, controlling temperature, and following safety precautions are key elements in this process. Regular quality control, environmental considerations, and compliance with regulations further contribute to responsible bitumen management. By implementing these practices, you can ensure the longevity and effectiveness of bitumen in various applications.