Bitumen is a crucial component in the construction industry, and it is used for various applications such as road surfacing, roofing, and waterproofing. Different grades of bitumen are available in the market, with two of the most commonly used grades being Bitumen 60/70 and Bitumen 80/100. This article will explore the differences between these two grades of bitumen, including their production processes, geographical influences on the market, and any advantages one may have over the other.

How Does the Production Process Differ?

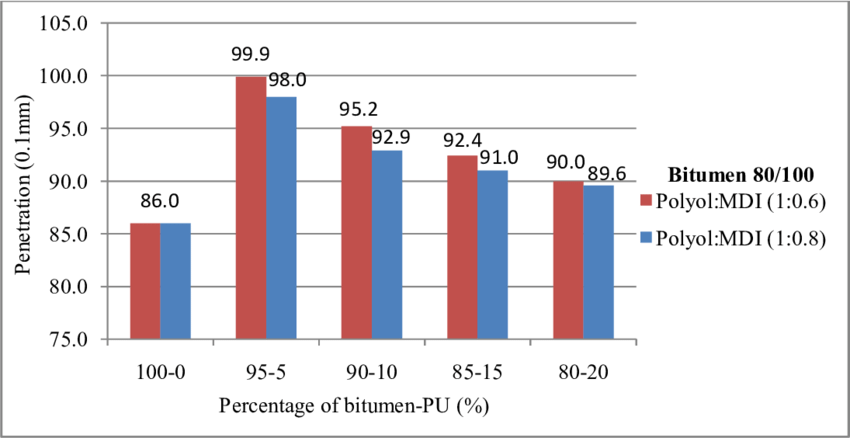

Bitumen is a byproduct of the refining process of crude oil. The production process for Bitumen 60/70 and Bitumen 80/100 is similar, but the main difference lies in the penetration value. Penetration value is a measure of the hardness or softness of bitumen, which indicates how much a standard needle penetrates the bitumen sample under specific conditions.

Bitumen 60/70 has a penetration value of 60-70 dmm, which means it is softer and more viscous compared to Bitumen 80/100, which has a penetration value of 80-100 dmm. The production process for Bitumen 60/70 involves heating the crude oil to high temperatures to separate the bitumen from other components. This process results in a softer and more viscous bitumen product.

Bitumen 80/100, on the other hand, is produced by heating the crude oil to even higher temperatures, resulting in a harder and less viscous bitumen product. This makes Bitumen 80/100 more suitable for applications where higher temperatures are involved, such as in hot climates or for high-traffic roads.

Example: In a study conducted by the Indian Institute of Technology, it was found that the production process for Bitumen 60/70 requires heating the crude oil to approximately 160-170°C, while Bitumen 80/100 requires temperatures of around 180-190°C1.

Do Geographical Factors Affect the Market of Each?

Geographical factors can play a significant role in the market demand for Bitumen 60/70 and Bitumen 80/100. The climate of a region can influence the choice of bitumen grade used for construction projects. For example, in colder climates, Bitumen 60/70 may be preferred due to its softer and more viscous nature, which allows it to withstand temperature fluctuations without cracking.

In contrast, in hotter climates, Bitumen 80/100 may be the preferred choice due to its harder nature, which makes it more resistant to deformation under high temperatures. Additionally, the availability of raw materials and infrastructure for refining bitumen can also impact the market for each grade.

Example: In Canada, where temperatures can drop significantly during winter, Bitumen 60/70 is commonly used for road construction to prevent cracking due to freeze-thaw cycles. Conversely, in the Middle East, where temperatures can soar, Bitumen 80/100 is preferred for its ability to withstand high temperatures without softening2.

Does any of them have any advantages over the other?

Both Bitumen 60/70 and Bitumen 80/100 have their own set of advantages depending on the application and environmental conditions. Bitumen 60/70 is more flexible and easier to work with, making it suitable for road construction projects in colder climates where flexibility is essential to prevent cracking.

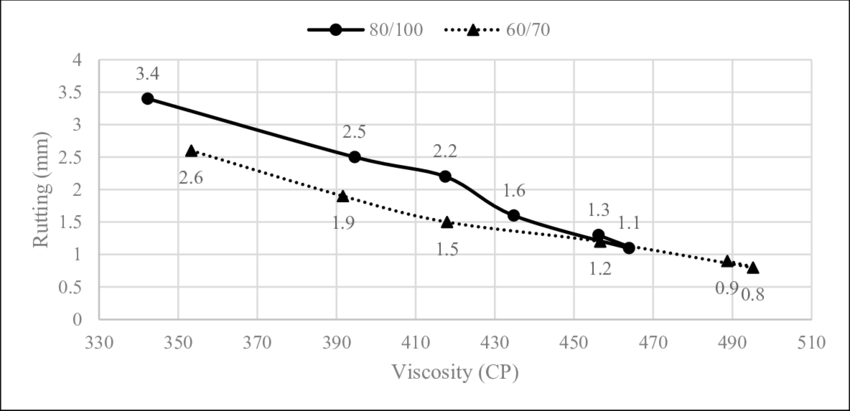

On the other hand, Bitumen 80/100 is more durable and resistant to high temperatures, making it ideal for road construction in hot climates or areas with heavy traffic. The harder nature of Bitumen 80/100 allows it to withstand the wear and tear of heavy vehicles without deforming or rutting.

Example: A study by the American Association of State Highway and Transportation Officials (AASHTO) found that roads constructed with Bitumen 80/100 in Texas, a region with high temperatures, showed less rutting and deformation compared to those constructed with Bitumen 60/703.

Additional Considerations

Environmental Impact: The production and use of different grades of bitumen also have environmental implications. Bitumen 60/70, being softer, may require more frequent maintenance and repairs, leading to higher emissions over the lifecycle of a road. Bitumen 80/100, while more durable, requires higher production temperatures, which can result in higher initial emissions.

Cost: The cost of bitumen can vary based on the grade and the region. Bitumen 80/100, due to its higher production temperatures and durability, may be more expensive than Bitumen 60/70. However, the long-term savings from reduced maintenance can offset the initial higher costs.

Example: In a cost-benefit analysis conducted by the European Asphalt Pavement Association, it was found that while Bitumen 80/100 had a higher initial cost, the overall lifecycle cost was lower due to reduced maintenance and longer service life4.

Environmental Sustainability

Environmental sustainability is an increasingly important consideration in the construction industry, and the choice of bitumen grade can have significant environmental implications.

Production Emissions: The production of bitumen involves heating crude oil to high temperatures, which results in the emission of greenhouse gases. Bitumen 80/100, which requires higher production temperatures, may have a higher carbon footprint compared to Bitumen 60/70. However, advancements in refining technology and the use of cleaner energy sources can help mitigate these emissions.

Lifecycle Impact: The environmental impact of bitumen extends beyond production to its entire lifecycle, including application, maintenance, and disposal. Bitumen 60/70, being softer, may require more frequent maintenance and repairs, leading to higher emissions over the lifecycle of a road. Bitumen 80/100, while more durable, can reduce the frequency of maintenance, thereby lowering the overall environmental impact.

Recycling and Reuse: Both grades of bitumen can be recycled and reused in road construction, which helps reduce the demand for new raw materials and minimizes waste. The recycling process involves milling the old asphalt pavement, reprocessing it, and incorporating it into new pavement mixtures. This practice not only conserves resources but also reduces the environmental footprint of road construction projects.

Example: According to a report by the National Asphalt Pavement Association (NAPA), the use of recycled asphalt pavement (RAP) in the United States saved approximately 60 million tons of virgin aggregate and 3.8 million tons of asphalt binder in 2019, significantly reducing the environmental impact of road construction.

Innovative Solutions: The industry is also exploring innovative solutions to enhance the sustainability of bitumen. For instance, the incorporation of bio-based additives and modifiers can improve the performance of bitumen while reducing its environmental impact. Additionally, the development of warm mix asphalt (WMA) technologies, which allow asphalt to be produced and laid at lower temperatures, can further reduce greenhouse gas emissions and energy consumption.

Example: A study by the European Asphalt Pavement Association found that the use of WMA technologies can reduce energy consumption by up to 30% and greenhouse gas emissions by up to 15% compared to traditional hot mix asphalt (HMA) production.

Conclusion

Both Bitumen 60/70 and Bitumen 80/100 have their unique characteristics that make them suitable for different applications. The choice between the two grades depends on factors such as climate, traffic conditions, and project requirements. Understanding the production process, geographical influences and advantages of each grade can help in making an informed decision when selecting the appropriate bitumen grade for construction projects.

By considering factors such as environmental impact, cost, and specific project needs, stakeholders can choose the most suitable bitumen grade to ensure the longevity and performance of their construction projects.